Industrial Lighting Drives Precision in Manufacturing and Beyond

Industry 4.0 has taken off – technologies such as artificial intelligence (AI), Internet of Things (IoT), and innovations in automotive, solar and semi-conductor require precision machinery for creating these modern marvels. Industrial lighting and lasers play a central part in manufacturing these products with round the clock operations demanding the highest quality light sources. These lamps are also used beyond tech manufacturing, with applications in food production. As the leading provider of lighting and laser lamps, we thought we would provide you with a closer look at the many applications and benefits of industrial lighting with lamps Amglo produces.

Laser lamp applications expand manufacturing boundaries

According to the The American Society of Mechanical Engineers, “laser machining can create fine features that are difficult or impossible to make using traditional machining equipment. Laser cuts are super-clean with no burrs or heat effects to the surrounding material, thereby eliminating the need for some secondary finishing steps.” Amglo manufactures xenon flashlamps offering this level of precision:

Laser cutting: Xenon flashlamps can be used for non-contact laser cutting resulting in high quality dimensionally accurate cuts.

Laser welding: Xenon flashlamps provide laser welds formed as the intense laser light rapidly heats the material.

Laser marking: Xenon flashlamps are used as a method to mark materials using a fine spot diameter to enable tracking and traceability across many industries.

Additionally, Amglo offers a water-cooled krypton laser lamp (AQH-8953) for micro spot welding or fine cutting applications. More information on this lamp can be found here.

Industrial lamps beyond laser

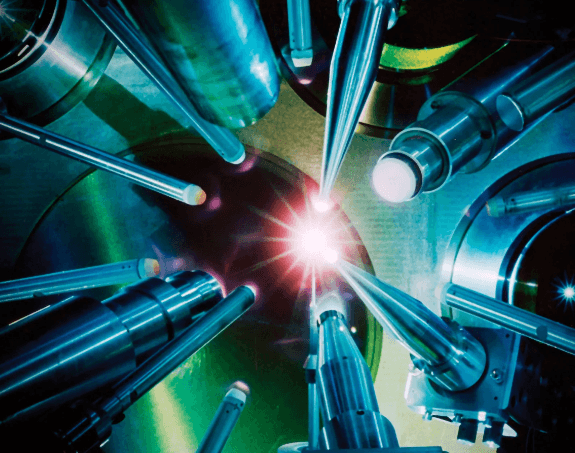

Xenon flashlamp lighting also provides many industries with a wide range of applications used in several sectors including food and water disinfection, curing and semiconductor fabrication.

Curing: Xenon flashlamps are ideal for curing applications due to its broad spectrum, high intensity which generates low heat to substrate material.

Rapid thermal processing / epitaxy: Used in semiconductor fabrication either to create a perfect crystalline foundation layer on which to build a semiconductor device or to alter mechanical attributes of an underlayer in a way that improves its electrical conductivity.

Food processing and water treatment: Pulsed light can be used as a powerful disinfection or decontamination tool by destroying the cellular structure of organisms.

Amglo has developed quality products for industrial purposes where success is measured by efficiency, productivity, and overall cost of ownership. Amglo’s lamps for industry provide high reliability, optimum performance and a long lifetime. Be sure to download our Cosmetic and Laser Lamp Catalog and contact us for more information.