UNIQUE MANUFACTURING CAPABILITIES

Amglo, with an 85-year history of innovation, is recognized for its ongoing ability to offer a diversified approach to lamp technology and production. Amglo’s global manufacturing facilities provide a variety of lamp products that include xenon, halogen, metal halide and laser to meet specific customer needs with delivery lead times of under four weeks. Amglo’s Xenon lamp division, located just outside Chicago, is the largest xenon flash lamp manufacturer in North America. This facility has over 1,600 different lamp designs ranging from 1 – 2 Watts to 1800 Watts.

Our manufacturing facilities provide the capabilities:

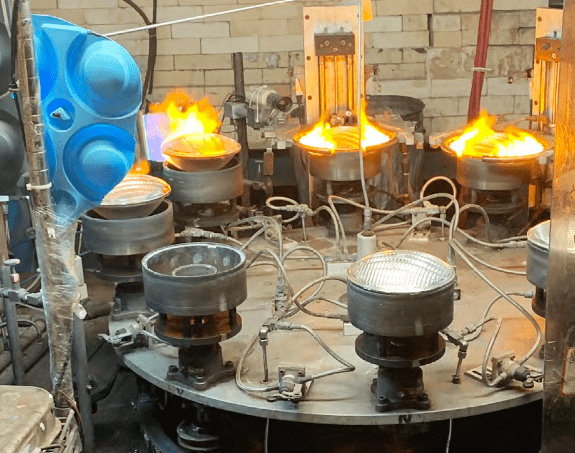

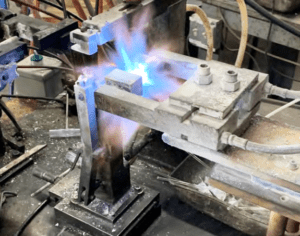

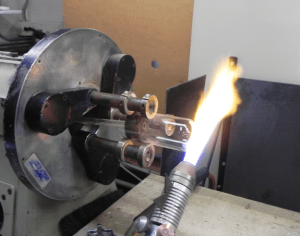

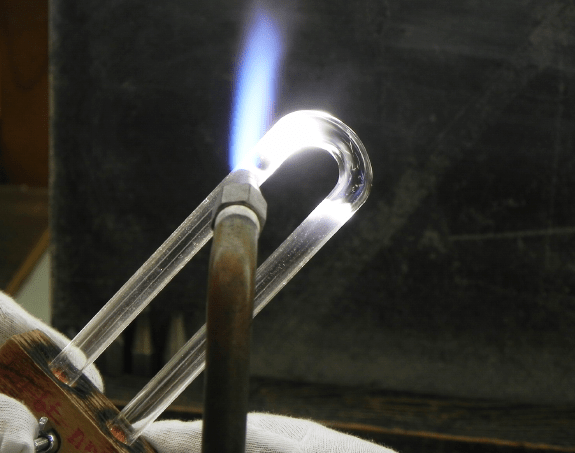

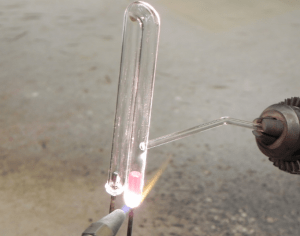

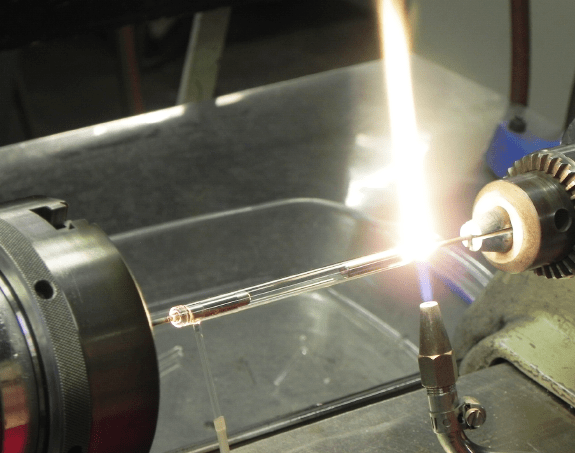

- In-house glass blowing and molding resulting in bodies of all shapes and sizes.

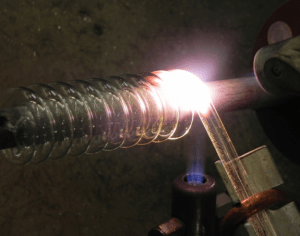

- Vertically integrated in-house filament and winding development tailored to each customers requirement.

- Quartz & glass envelope construction and customization.

- Proprietary cathodes and electrodes are manufactured “in house” and processed in lamps on the same day; pressed and sintered.

- Vertically integrated in-house filament and winding development tailored to each customers requirement.

- Manufactured filaments used in halogen capsules allow for full customization of products.

- Quartz & glass envelope construction and customization.

- Light output testing designed specifically to each customers requirement.

- Engineering and R&D lamp research allow for ‘best of class’ lamp development.

- Cathode metallurgy including advanced additives for superior lifetime.

- In-house research and development and technology technicians.

- ISO Certified, ISO 9001 & Medical ISO 13485.