The Future of High-performance Electronics? Precision Laser

We have been sharing a lot about the many uses of lasers in the world of advanced manufacturing on social media this month. What makes laser welding so valuable is its ability to create incredibly precise, high-strength bonds without physically touching the materials. And now, as technology products become smaller, smarter, and more complex, industries are beginning to rely on laser technology to deliver the speed and accuracy modern production demands with its ability to join materials with minimal heat input and near-zero distortion, especially in electronics.

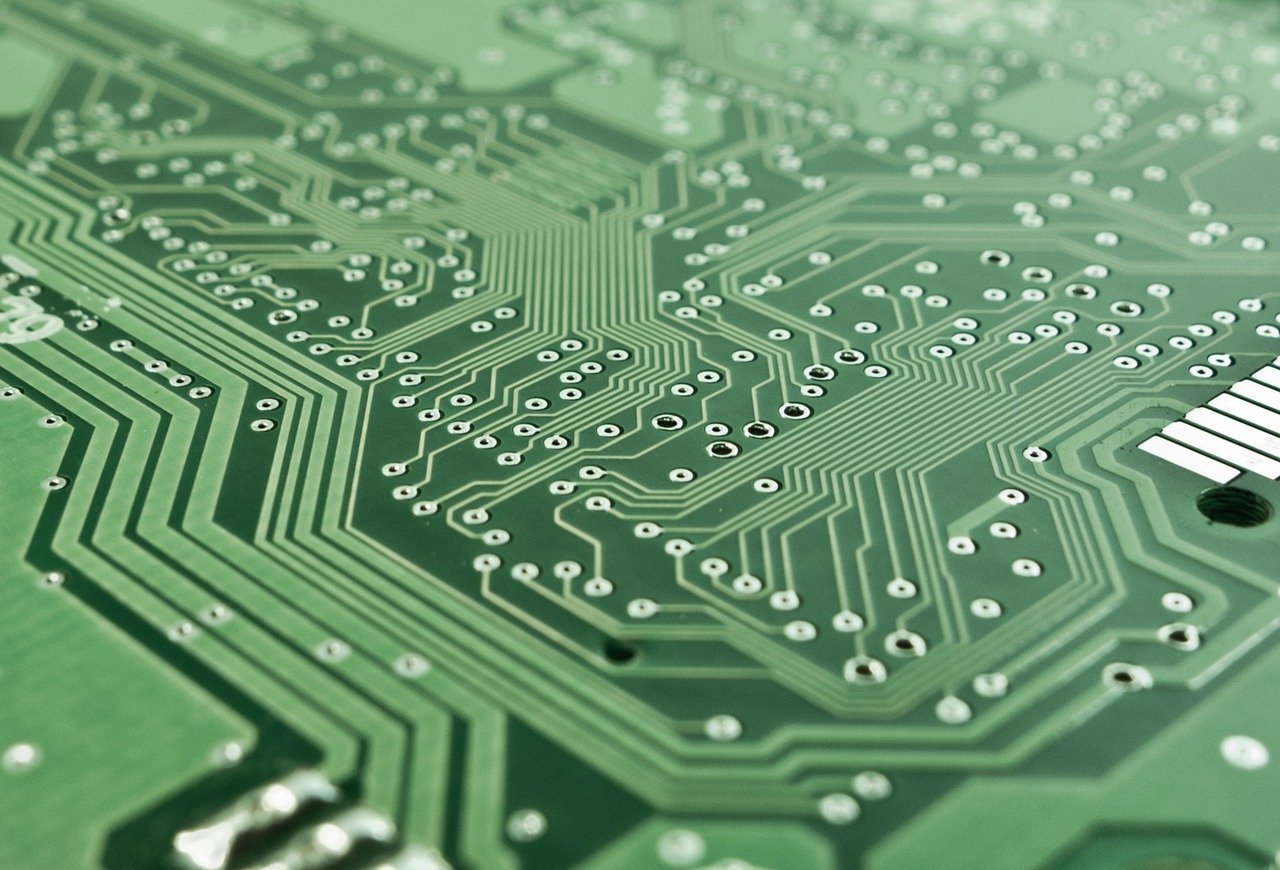

This is critical when working with fragile or intricate parts, such as circuit boards, sensors, or microchips. Poor precision in laser assembly can lead to major consequences, resulting in device failure and increased manufacturing costs. For example, a lack of precision can cause thermal damage, delamination, or cracking in fragile materials, which are not easily detected by the naked eye. Additionally, without high repeatability, each assembled device could vary in quality, increasing product variability and decreasing overall manufacturing yield.

The focused nature of the laser beam allows manufacturers to maintain clean welds on delicate assemblies, often with dissimilar materials or even plastics, while avoiding contamination or damage. It’s a fast, efficient, and repeatable process that significantly reduces post-processing and improves overall product quality.

As the need for precision continues to grow, so does the need for dependable, high-performance components within the laser systems themselves. In industries like microelectronics and optoelectronics, where even minor flaws can compromise functionality, laser precision is essential. Whether connecting battery tabs in EVs or aligning components in fiber optic systems, the margin for error is incredibly small. Laser welding not only meets these demands but often exceeds traditional methods in speed, cleanliness, and long-term reliability.

Responding to evolving demands for laser accuracy

We understand the critical need for precision. As technology continues to advance, Amglo continues to adapt. Our years of consistency when it comes to innovation in flash lamp technology allows our laser lamps to maintain that critical level of precision over time, supporting today’s demand for delicate electronics assembly.

The laser lamps chosen for such important work as emerging electronics must perform reliably over long service lives—even under the tightest tolerances. When accuracy, speed, and reliability matter, it is good to know that Amglo is the light behind the laser.