Industrial Lamps

The choice of leading OEMs, Amglo’s lamps are widely used throughout the automotive, aerospace, solar and semi-conductor manufacturing sectors where round the clock operations demand the highest quality light sources for applications that include welding, engraving, weathering, curing and inspection. With a focus on high reliability, optimum performance and long lifetime, Amglo has developed a range of products for industrial purposes where success is measured by efficiency, productivity, and overall cost of ownership.

Specific Lamp Uses

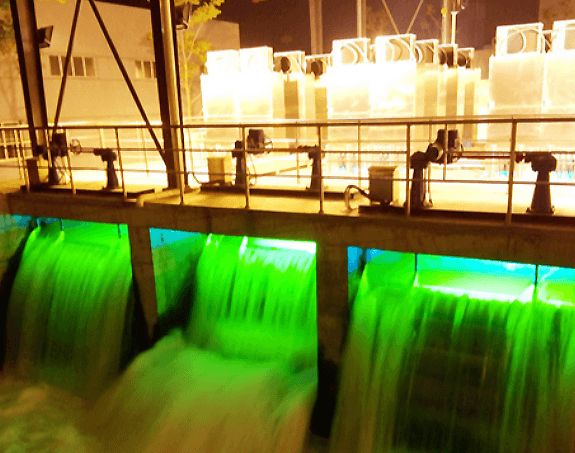

Water Treatment

Xenon Flash Lamps can be utilized to killing pathogens in the area of water treatment by destroying the cellular structure of organisms.

Curing

Xenon flashlamps are ideal for curing applications due to broad spectrum, high intensity and generate low heat to substrate material.

Food Processing

Xenon Flash Lamps help with concerns over food contamination in the food processing industries. Pulsed light as a more powerful disinfection tool.

Sterilization

Xenon flash lamp has proven to be a viable technology for disinfection/sterilization applications. Pulsed light as a more powerful disinfection tool.

Laser Marking

Xenon Flash Lamps can be used as a marking method to mark materials using a fine spot diameter to enable tracking and traceability across many industries.

Laser Welding

Xenon Flash Lamps can be used for laser welds formed as the intense laser light rapidly heats the material.

Laser Cutting

Xenon Flash Lamps can be used in the for non-contact laser cutting resulting in high quality dimensionally accurate cuts.

Rapid Thermal Processing / Epitaxy

Used in semiconductor fabrication either to create a perfect crystalline foundation layer on which to build a semiconductor device or to alter mechanical attributes of an underlayer in a way that improves its electrical conductivity. Amglo has spent considerable engineering efforts to design the most reliable and effective lamps in the semiconductor manufacturing industry. Amglo lamps provide extended uptime for epitaxy equipment and are manufactured to very strict quality processes.