A Quick Guide to Amglo’s Custom Lighting Technologies

Amglo offers a wide range of cutting-edge lighting technologies, from cosmetic procedures that require intense pulsed light to quality controls that support the development of clean, renewable energy. While the versatility of our products means they have uses across various industries, we also understand that often customers come to us with a distinct set of needs and goals—which is why we maintain a strong commitment to offering custom lighting solutions.

This month’s blog post highlights our ability to design custom solutions that align with our customers’ unique objectives and infrastructure. In addition, we’ll take a look at the various tests and controls that ensure our customers receive the highest quality product available.

Research and Design (R&D) for custom solutions

Time can present a significant challenge when moving from concept to product, but at Amglo it doesn’t have to be an obstacle. By continuously optimizing our in-house research, development, testing, and quality control processes, we’re able to offer efficient turnaround times to clients who seek custom solutions, including for scientific, industrial, medical, disinfection, and cosmetic treatment lamps. Amglo’s approach to R&D includes the following capabilities:

• Speed to market prototyping, with new design prototypes delivered quickly.

• Advanced in-house teams that include R&D and technology technicians.

• Pressing, sintering, and processing of proprietary cathodes at our in-house machine shops.

Manufacturing facilities that enable custom design

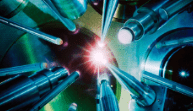

Throughout our nearly 90-year history of innovation, we’ve been recognized for our unique manufacturing capabilities. Our global manufacturing facilities provide a variety of xenon, halogen, metal halide, and laser lamp products with rapid delivery lead times. These products can also be customized to meet specific customer requirements, thanks to capabilities which include:

• In-house glass blowing and molding for a customized shape and size.

• Cathode metallurgy with advanced additives for superior lifetime.

• Envelope construction and customization, including quartz and glass.

Ensuring quality through rigorous controls

Among the most important reasons we’re able to offer the longest-lasting lamps on the market is Amglo’s commitment to quality control. Our testing and certification process reflects our constant pursuit of product innovation in addition to ensuring batch-to-batch quality that translates to superior field performance. Here are a few of our in-house quality controls:

• Vibration and environmental tests, which simulate realistic field conditions and are monitored daily by project engineers.

• Photometric and spectral measurements, performed at our in-house light laboratory.

• On-site monthly quality audits, which ensure that Amglo customers only receive products of the highest quality.

Amglo has been a leading manufacturer of specialty lamps since 1935, with products that have applications in aerospace, medicine, automotives, railroads, lasers, and more. While we take pride in the versatility of our products, we also know that lighting solutions can’t be of one-size-fits all, which is why we’re committed to offering affordable, high-quality custom options that meet your company’s individual needs.

Ready to discuss your ideas for a custom lighting solution? Contact us via our website.