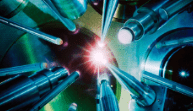

Why Laser Technology Has Become Essential Across Industries

From the operating room to the factory floor, lasers are transforming how businesses approach complex challenges that demand accuracy, consistency, and reliability. The demand for high-quality laser systems, and the specialized lamps that power them, has never been greater.

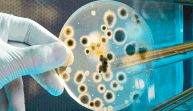

Transforming Medical Manufacturing

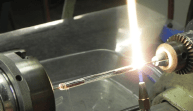

Laser technology’s impact on the medical manufacturing sector has been nothing short of revolutionary. In this field where precision can mean the difference between life and death, lasers have become indispensable tools in the creation of life-saving devices. Laser systems enable manufacturers to produce intricate medical implants with tolerances measured in micrometers, cut delicate surgical instruments with unprecedented accuracy, and create biocompatible surfaces that promote healing.

Consider the production of cardiac stents: Laser cutting allows manufacturers to create complex geometric patterns in metal tubes thinner than a human hair; these patterns must be perfectly executed to ensure the stent expands properly and maintains structural integrity within the human body. Similarly, laser welding is crucial in creating hermetic seals for pacemaker batteries and other implantable devices, ensuring they function well for years or even decades.

The pharmaceutical industry also heavily relies on laser technology for precision dosing in drug manufacturing, where laser systems help create consistent tablet scoring and enable the production of controlled-release medication formulations. This level of precision simply wasn’t achievable with traditional manufacturing methods.

Laser Applications Across Other Industries

While medical manufacturing showcases laser technology’s life-saving applications, numerous other industries have embraced this precision innovation. In aerospace manufacturing, lasers cut lightweight composite materials for aircraft components while maintaining the structural integrity essential for safe flight. The automotive industry uses laser systems for everything from cutting body panels to welding engine components, enabling the production of lighter, more fuel-efficient vehicles. Electronics manufacturing has also been transformed by laser technology’s ability to create microscopic features on circuit boards and semiconductor wafers. As devices become smaller and more powerful, laser systems and the precision they offer become increasingly vital.

Powering Precision Manufacturing

At the heart of every laser system lies a critical component that often goes unnoticed: the lamp. These specialized lamps provide the energy source that makes laser precision possible, and their quality directly impacts the capability, reliability, and longevity of the entire system.

Amglo’s lamps are designed to meet the exacting standards required across all laser-dependent industries, and the company has established itself as the trusted choice for manufacturers who demand excellence in their laser applications.

What sets Amglo apart is our unwavering commitment to quality and consistency. Our manufacturing processes ensure that each lamp meets strict specifications. When a medical device manufacturer needs to maintain consistent laser output for critical surgical instrument production, or when an aerospace company requires unwavering performance for cutting carbon fiber components, they turn to Amglo.

Our extensive product line covers the full spectrum of laser applications, ensuring that regardless of your industry or specific requirements, Amglo has the right solution. We understand that in precision manufacturing, there’s no room for compromise, and we’ve built our reputation on delivering lamps that perform consistently day after day, year after year.

Continuing the Future of Precision

As laser technology continues to evolve, Amglo remains committed to providing the lamps that power the innovations shaping our future.